- Who we are

- Our Products

- Hospital & Healthcare

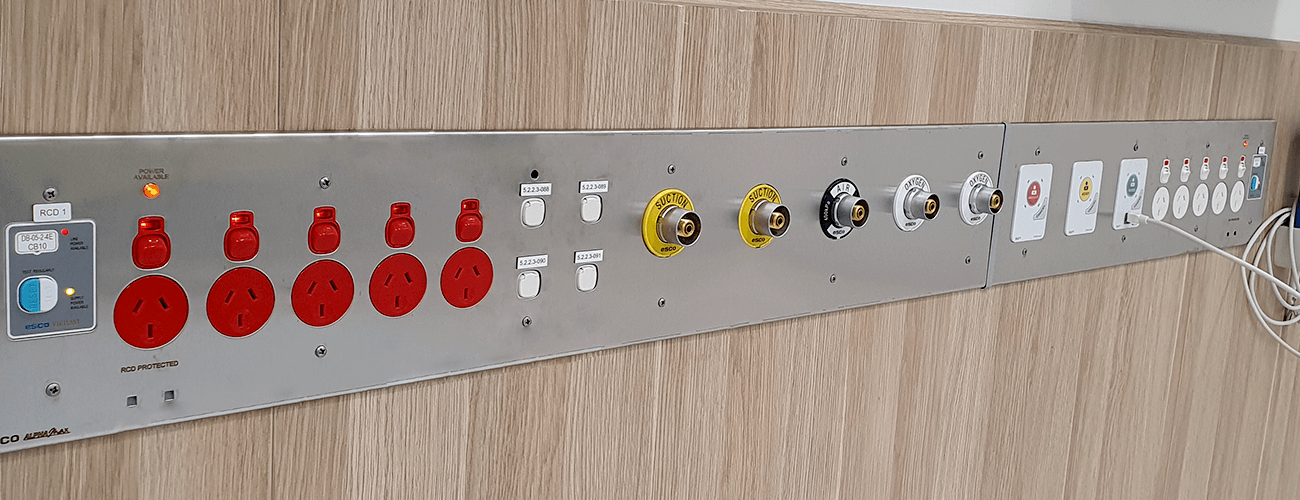

- Medical Services Panels (MSPs)

- Medical Gas Outlets

- Medical Gas Isolation Valve Boxes

- Residual Current Devices (RCDs)

- Medical General Purpose Outlets (GPOs)

- Line Isolation Devices and Monitoring

- Medical Lighting

- UPS Status Indicator

- Medical Services Pendants

- Equipotential Junction (EPJ) Panels & Test Points

- Solid Plate Switchgear – Tamper Proof

- Medical Gas Hose Assemblies & Fittings

- Medical Area Signs

- See more

- Aged Care

- Mental Health

- Commercial

- Prison/Correctional

- Hospital & Healthcare

- Projects

- Contact